Research and Development

We understand, design, and optimise energy storage systems through patented technology solutions

World Class

Research &

Development

Facilities

At our core lives a spirit of innovation. At Redx™ Research we enable future solutions by developing pragmatic technology solutions that can be applied in many applications across many sectors. Redx™ Research is the link between people, business and technology. Together with our partners, we bring bold ideas to life.

Redx™ Research’s mission is to develop tomorrow’s technology for industry needs. We understand that needs are changing constantly with the ever-changing world. By being at the front of the pack we can help shape the future with innovative solutions.

Over 30 Patents

AUSTRALIAN R&D CENTRE

Ultra High efficiency

Electrolytic

Capacitorless

Technology

Less Hardware Less Weight

Increased EfficienciesIncreased Saving

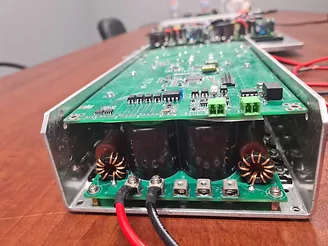

E-Capless™ Technology eliminates traditional electrolytic capacitor inverters with a new inverter topology that requires no electrolytic capacitors. Electrolytic capacitors is one component in an inverter that is the first to fail. By developing a way to eliminate the need for electrolytic capacitors in our inverters, allows us to reduce the hardware cost, reduce the weight and increase the life span of the inverter by 30%, ultimately lowering the overall cost of the hardware components.

Australian

Research & Development

As one of the Australia’s leading companies in inverter systems, Redx™ focuses on innovative power conversion technology. In 2013, Redx™ Filed for their first patent and since then, have continued to bring game changing technology to life, and started to build a in-house research facilities that specialize in continuing R&D and product testing for further development and client customization.

Located in our Head Office in Gold Coast city, Australia, Redx™ ‘s main laboratory covers all the design and engineering for all new products and designs. Redx™ also has an international R&D center located in Shenzen, China. Our Labs are Equipped with full DC and AC testing equipment, HIL testing, and other instruments for electrical testing, fully staffed with experienced engineers, testing specialists, and electricians to compliment a full R&D team.

Inverter Technology

Leaders

The advanced inverter technology developed by Redx™ Technology Australia is world first, game changing opportunity that will evolve the industry in DC-DC and AC -DC inverter topologies. This technology opens multiple possibilities for higher efficiencies, smaller footprints and overall significant reduced cost of manufacture.

Custom designed hardware for your next project

Australian Patented Technology

What sets Redx™ Technology apart from our competitors is our unique patented inverter technology. These unique technology advantages allow Redx™ a leading technological edge to provide new solutions to existing problems. Proudly designed and engineered in Australia. Redx™ has over 30+ patents in electronics inverter technologies.

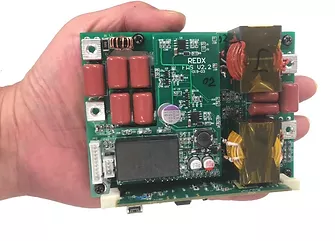

FWS Inverter

Palm size 1500w Micro Inverter

- Hand sized

- Reduce manufacturing cost

- Reduce size of hardware

- Using conventional MOSFETs to achieve 99% efficiency

- Non-series structure to achieve bi directional energy flow

E-Capless™

Electrolytic Capacitorless Technology

- World First Technologies

- No Electrolytic Capacitors

- Reduce manufacturing cost

- Reduce size of hardware

- Increased lifespan 30%

Software

Software Solutions

- VPP Ready

- Super fast response

- Embedded Software into Inverter

- Wifi/4S485/4G connections

- Web Based

- IOS/Android

Single Stage DC-AC

Single Stage DC-AC Technologies

- World First Technologies

- Ultra High Efficiencies

- Reduce manufacturing cost

- Reduce size of hardware

Software Technology Leaders

Redx™ Software R&D team based in Australia have developed an APP and Web based software solution. Software is the key part to the success of our inverters. All Redx™ Inverters have been designed with embedded software, eliminating the need for third party monitoring devices for VPP operation.